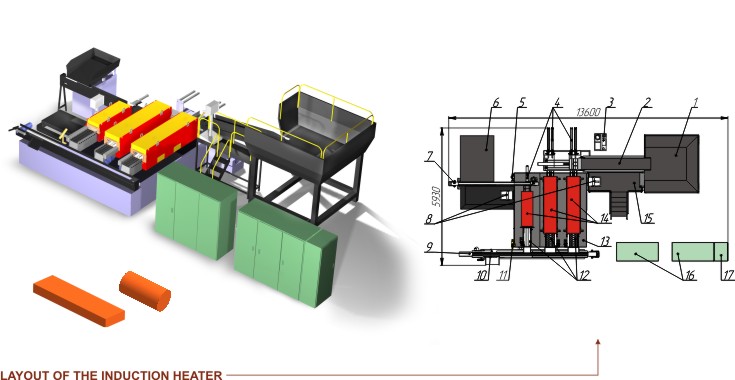

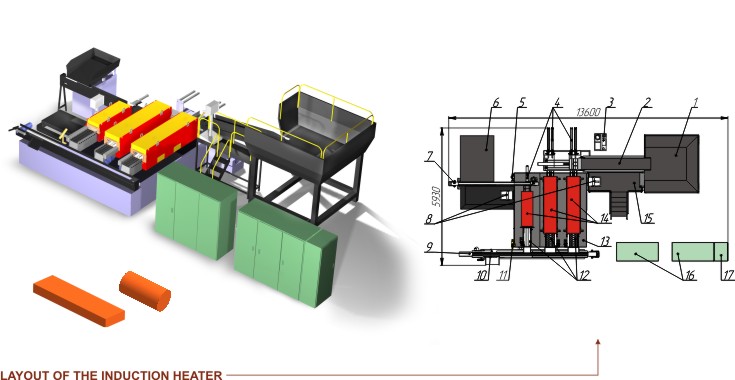

INDUCTION HEATER IH 1600 (model IH 1600-B-1,3-4-2)

BASIC DELIVERY SET

- Receiving bunker

- Collecting tray

- Hydraulic drive

- Mechanism for feeding billets into the inductors

- Pneumatic drive

- Vibration exciter for feeding

- Chain conveyor

- Control board

- Press loading conveyor

- Separating mechanism

- Pyrometer

- Mechanism for unloading the inductors

- Induction heater cabinet

- Inductors

- Operating platform

- Frequency converter

- Electric equipment cabinet

DELIVERY SET INCLUDES

- Operations manual

- Inductor drawings

- Set of spare parts

ITEM DIMENSIONS

Cylindrical:

- Diameter 65-150 mm

- Length up to 400 mm

Prismatic:

- Length 280 mm

- Height 36 mm

- Width 100 mm

OPERATING CHARACTERISTICS

- Operation mode is automatic, according to programmed requirements

- Output rate 3700-4000 kg/hour

- Maximum power – 1600 kW

- Supply voltage – 380 V

- The billets are heated automatically in specified temperature interval

- Maximum heating temperature – 1300 C°

- Readjustment time with inductor exchange – 1 hour

- Cooling water pressure 0,3-0,4 MPa

- Cooling water rate 22 m³/hour

- Compressed air pressure 0,4-0,5 MPa

- Compressed air consumption – 1,5 m³/min

- Weight 7 tons

- Floor space covered 81 m², is based on 300 mm thick concrete bottom

THE INDUCTION HEATER IS EQUIPPED WITH

- Software control system on the base of “OMRON”, “Siemens” processors and others

- Protection system preventing billets welding in the inductor

- Billets heating temperature control system

- Billets separating system according to the temperature

- System protecting induction coil from overheating

- Billets heating temperature automatic control system

ADDITIONS TO BASIC DELIVERY SET

- Inductors

- Device for transporting heated billets

- Smooth feeding system of the billets into the inductor

- Tipping device for workshop containers

SERVICE

- Induction heater installation and adjustment at the customer’s facility

- Personnel training at equipment operation

top