The traditional design of mining tools includes the body with a landing butt-end and cutting surface with the hard insert, mounted on its spike. The stability of a mining tool depends on that of the hard insert and the body. These factors are interlocked by the speed of cutter lengthwise deterioration. The best result is reached provided that the hard insert deterioration speed is equal to the body deterioration speed and the cutter is worn out equally on the whole perimeter. When the body deterioration precedes the hard insert casing vanishes and the insert comes out later.

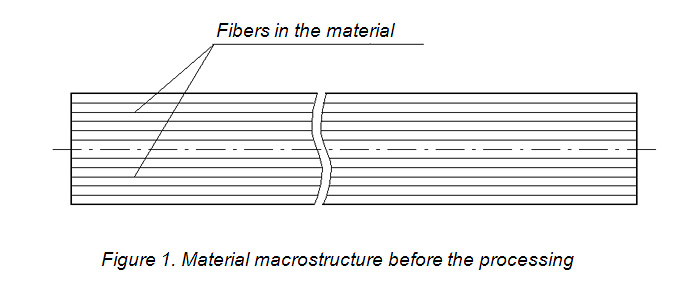

Up to the present moment the basic methods of the mining cutter body production were cutting and punching. Depending upon the production technology the cutter body acquires the macrostructure that is typical for the technology. The cutter body is produced from a rolled bar. The macrostructure of a source material contains the continuous fibers directed along the generating line and distributed quite evenly along the section (Fig. 1).

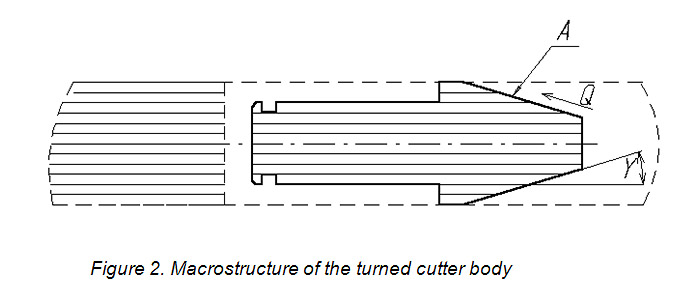

During the production of the cutter by means of turning (cutting) this material some fibers are cut away. They become interrupted (Fig. 2) which, as known, reduces the total stability of the body considerably. On the cutting area the fibers come to the work surface (A) generator at the g angle. As long as the cutter works the friction force (Q) affects along the (A) surface. The direction of (Q) force is the same as of the generator. It’s obvious that this circumstance causes the reduction of material stability in the direction of the friction force affection. The stability reduction value is proportionate to the g angle sine.

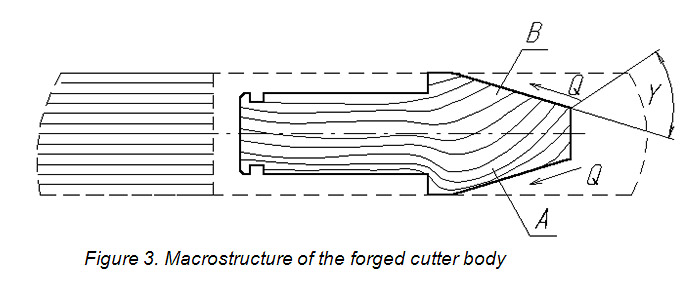

When the method of punching is applied the bar is deformed which causes the flow of material. The dominating direction of material flow is cross to the axis and at the same time irregular. During the hot forging the fibers keep the continuous character. During the cold punching most of them lose the continuous character.

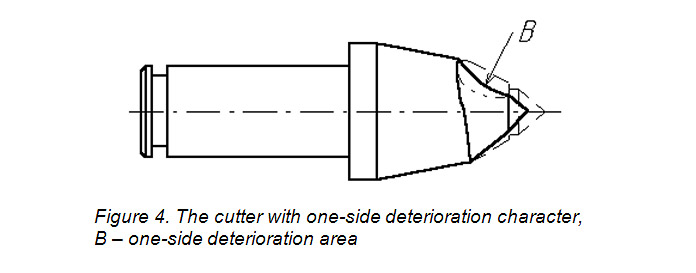

Figure 3 depicts the macrostructure typical for the hot forging process. The macrostructure of cutter body after the forging has two pronounced areas: (A) area, where the fibers are compressed to the surface and their direction is close to the (Q) friction force direction; and (B) area, in which the fibers are remote with a much greater distance than in (A) area and are directed at g angle to the (Q) friction force direction. The deterioration durability of the (A) area is great higher than that of the (B) area. Thus, on the work part of the product two areas of different stability – (A) and (B) are formed. The corollary of it is the uneven deterioration along the perimeter of the work part of the product. This phenomena together with the non-coaxiality of the work part relatively to the butt-end are the causes of the one-side deterioration. As shown on Fig.4, in (B) area either a plain or crater-shaped depression is worked out. The cutters beginning to deteriorate on one side stop rotating and the character of their further deterioration is avalanche-like. Usually the cutters with the primary one-side deterioration features are replaced before the deterioration is complete.

One of the corollaries of the insufficient cutter stability is its construction. The lack of stability of the body point material is compensated with the surplus mass of the material on the work surface so that the uneven advance deterioration relatively to the hard insert can be avoided.

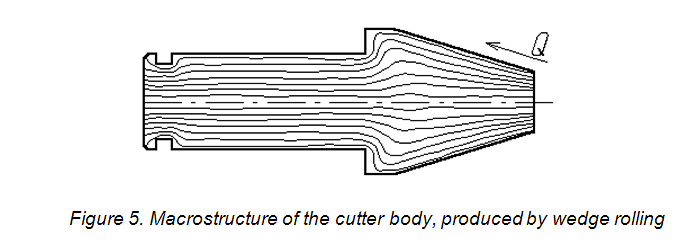

For the recent years JSC Beltechnologia & M have developed a new technology of cutter body production. It is a wedge rolling technology, that belongs to the hot deforming processes. During the wedge rolling the billet is deformed in radial direction while rotating. The material flow is directed along the billet axis. Such scheme of influence upon the billet allows to form axially symmetrical macrostructure with the continuous fibers, which are compressed to the surface and directed along the generator (Fig. 5).

The position of the fibers of the cutter body, produced by wedge rolling (Fig. 5) points out the possibility of forming the macrostructure that in the best way meets the operation requirements and allows to reach much higher stability than by turning or forging.

To check the assumed conclusions the industrial testing of the wedge-rolled mining tools was accomplished. The testing was performed in the mines of PE “Belaruskaliy”, Soligorsk and in the mines of Donetsk coal-fields.

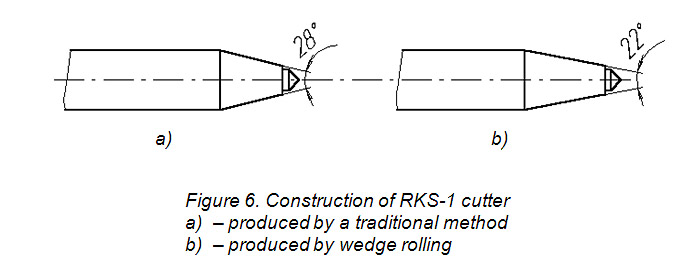

In the mines of PE “ Belaruskaliy ” the RKS-1 cutters, produced by means of cutting and wedge rolling were tested. As a result it was ascertained, that the deterioration stability of the tools was increased at about 30%. As a result the deterioration of the hard insert preceded that of the body. This allowed to change the structure of cutter. Its tool angle was reduced from 28O to 22O (Fig. 6). The reduction of the tool angle favoured the reduction of cutting force at within 5 % to 10 %. Accordingly the feeding speed per cutter was increased.

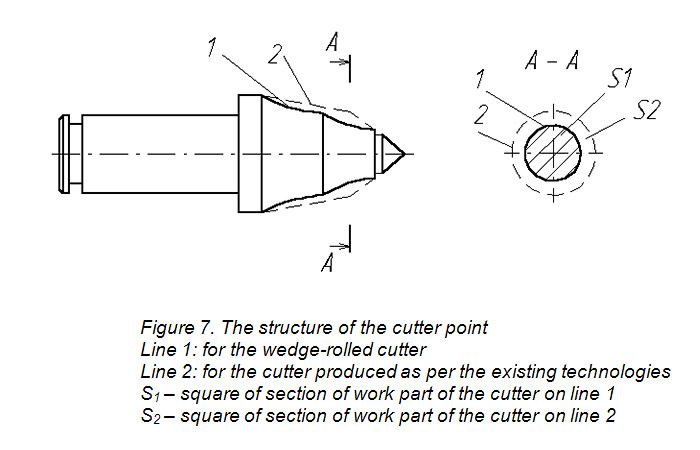

The results of cutters testing on PE “Belaruskaliy” were considered during the design of cutters for coal mining machines. Taking into account the information about the cutters deterioration stability and applying the analogy of approach the specialists developed a new structure of the point of the cutter for coal mining machines. The volume of the cutter work part was reduced at in average 30 %. On Fig. 7 the traditional structure of the point (line 2) is combined with the new one (line 1). The square (S2) of maximal section of the work part of the traditional cutter is reduced relatively to the square of section of the new cutter (S1) at 60 %.

The results of testing carried out on Krasnolimansk mine, Ukraine indicated that the cutters with wedge-rolled bodies were more than two times more durable.

Inference:

- Macrostructure of the mining tools body influences considerably its deterioration stability.

- The production of the bodies for mining tools by the method of wedge rolling increases their deterioration stability essentially.